With the pace of updating of the times, hardware stamping products can be seen everywhere in our daily life, and when we can see these products, they have been surface treated, and a covering layer is formed on the surface of the workpiece through a certain method, giving hardware stamping Anti-rust, anti-oxidation, anti-corrosion, more beautiful and improve the effect of product performance. So what are the surface treatment methods of metal stamping parts?

1. Electroplating: The plated metal or other insoluble materials are used as the anode, and the workpiece to be plated is used as the cathode. The cations of the plated metal are reduced on the surface of the workpiece to be plated to form a coating. The purpose of electroplating is to plate a metal coating on the substrate to change the surface properties or dimensions of the substrate. It can enhance the corrosion resistance of metals (coated metals are mostly made of corrosion-resistant metals), increase the hardness of stamping parts, prevent wear, improve electrical conductivity, lubricity, heat resistance and beautiful surface.

2. Galvanized tin: Galvanized tin refers to a surface treatment technology that coats a layer of zinc on the surface of metals, alloys or other materials for aesthetics and anti-rust effects. The main method used now is hot-dip galvanizing.

3. Spraying: Use pressure or electrostatic force to attach paint or powder to the surface of the workpiece, so that the workpiece has corrosion resistance and surface decoration.

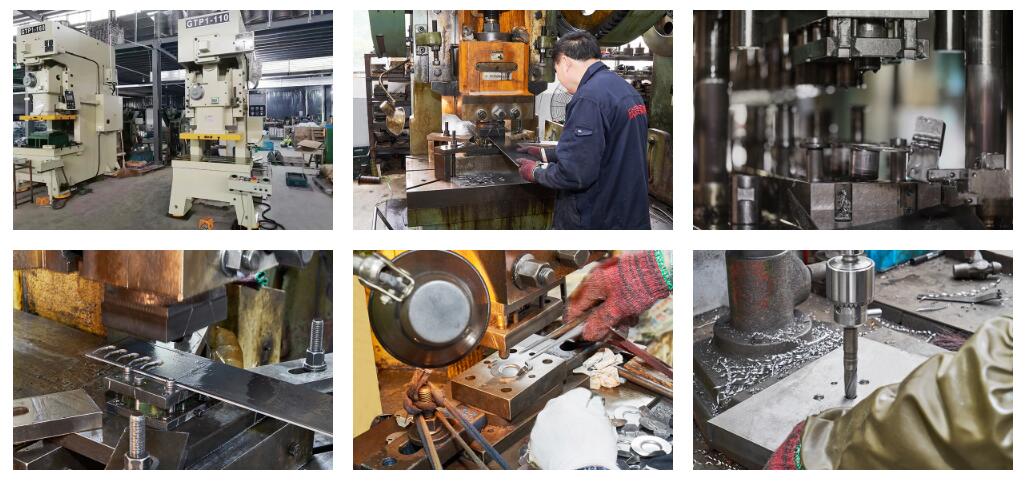

Ningbo Xinzhe Metal Products Co., Ltd has over 7 years of expertise in custom metal stamping production. Precision stamping and large-scale manufacturing of complex stamped components are the main focus of our factory. With refined production methods and cutting-edge industrial technology, we provide creative solutions to your difficult projects.Every product and process is evaluated from the premise of using the lowest cost materials—not the lowest quality—along with optimised production techniques that can eliminate as much non-value labour as feasible while still guaranteeing that the process can produce products of 100% quality.

Welcome to consult and cooperate!

Post time: Jul-03-2023