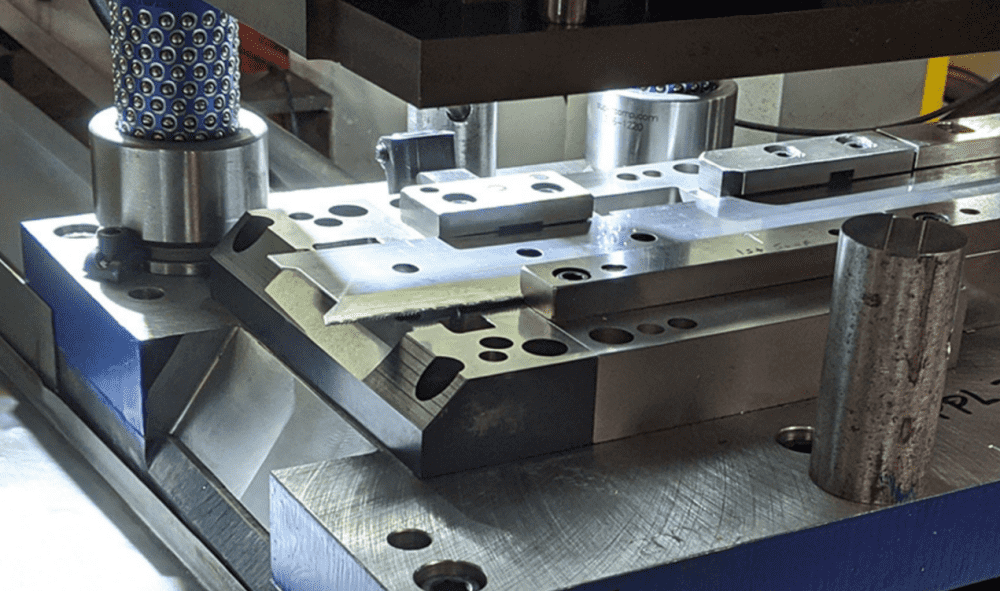

Placing flat sheet metal into a stamping press, often known as pressing, can be done in coil or blank form. The metal is shaped into the required shape in the press using a tool and die surface. Metal is shaped using stamping techniques such as punching, blanking, bending, coining, embossing, and flanging.(auto parts/hinge/ Gasket)

The manufacturing technique of metal stamping is used to form flat sheet metal into predetermined shapes. A range of metal forming processes, including punching, bending, and piercing, to mention a few, can be used in this intricate process.( Metal Bracket/ Corner Bracket)

Metal sheet shaping is the primary function of stamping equipment. A metal press could mould sheets to fit a form or contour. It creates a 3D format out of flat sheet metal. A metal brake is a device for accuracy that can bend metal sheet at angles up to 90 degrees. Shaped metal parts are frequently needed by the automotive, aerospace, and appliance industries.( Mending Plates Angle L Bracket/ Stainless Steel Bracket/ Aluminum Bracket)

Punching is another task performed by metal presses. By employing dies or a suitable-sized die, it is a cheap method of producing holes in metal sheet. The metal shells are pushed into the container by this procedure from the openings. Additionally, industries often recycle these waste materials into other products. A metal press might create a few holes of different sizes.

Punching and blanking are nearly identical. However, in this instance the slugs, not the holes, are the result of the procedure. Metal blanks can be used for a variety of things, including jewelry, dog tags, washers, fishing lures, and brackets.( Inner Bracket/ Heavy Duty Shelf Bracket)

Metal tooling is a different procedure. Software-assisted production creates specific, non-standard components for industries like aerospace that demand the highest level of precision and accuracy. This is usually a multi-stage press technique that produces parts to specification.

Deep drawing is another use for metal pressing. From metal sheets, it creates 3D items like tubes and cans. The tool thins and stretches the sheet to give it the desired shape, using CAM/CAD computer-generated designs to produce the vessels.( Steel Stamping/ Iron Wire Bracket)

In order to create an elevated pattern on the front of the piece, a metal press can also emboss metal sheet by stamping a design into the metal from the rear. Numerous businesses require stamped serial numbers, brand names, and other characteristics to be embossed on metal before it is incorporated into their products.( Custom Sheet Metal Bend Fabrication Black Powder Coating SPCC Bracket/ Metal Fabrication/ Auto Stamped Bracket)

The pressing process of coining involves imprinting intricate details onto the metal’s surface. It is quite similar to embossing. It is frequently more difficult, though. This process is widely used by producers to create precision goods like buttons, coins, jewelry, and other items. These comprise machine vent covers and decorative air duct grilles.( Non-Standard Precision Sheet Metal Fabrication Welded Large Metal Bracket/ OEM Sheet Metal Fabrication Service)

Post time: Dec-06-2022

.

.