Deep drawing is a manufacturing process that can create complex and intricately shaped metal parts. It is particularly suitable for the production of parts with high functionality and structural integrity. In this blog, we delve into the world of deep drawn parts, exploring what they are, their applications and their advantages over traditional manufacturing methods.

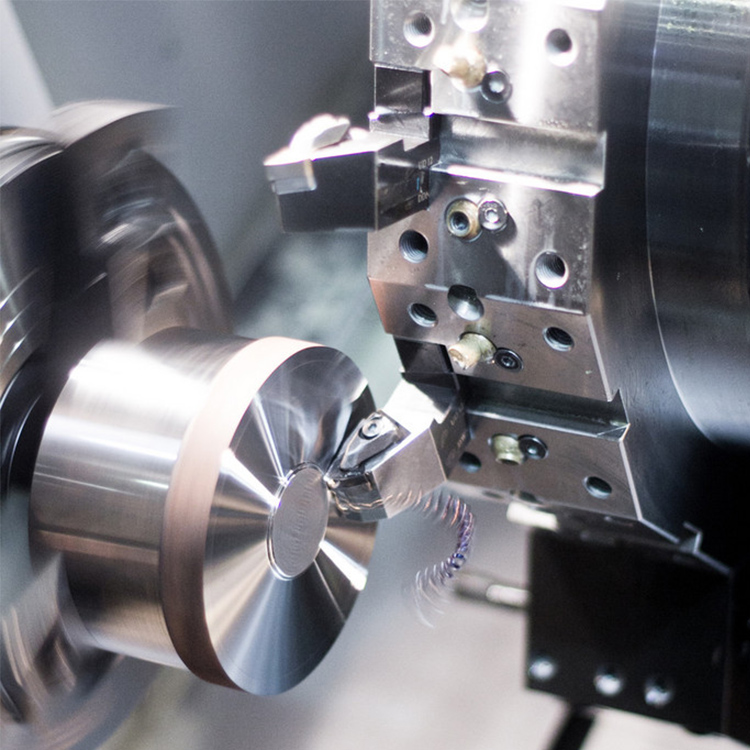

Metal deep drawing parts refer to parts formed by deep drawing and stamping processes. The method involves drawing and reshaping a flat metal blank into the desired shape using punches and dies. Material is forcefully drawn into the mold cavity, resulting in a smooth, dimensionally accurate finished part.

One of the main advantages of deep drawing is the ability to create complex geometries and shapes with excellent dimensional accuracy. This makes them ideal for industries such as automotive, aerospace, electronics, and medical, where precision and reliability are critical. Deep drawn parts are commonly used in applications such as engine components, fuel tanks, sensors and various types of housings.

Compared with other manufacturing techniques, the deep-drawing stamping process has several advantages. First, deep-drawn parts have exceptional strength and structural integrity due to the absence of seams or joints. This enhances the overall reliability and durability of the assembly. Second, deep drawing enables cost-effective mass production because it can produce large numbers of parts quickly and efficiently. Additionally, the process is highly repeatable, ensuring consistency and reliability for every part produced.

In addition, deep drawing provides excellent material utilization, minimizing waste and reducing overall material costs. The seamless nature of deep drawing can also improve part functionality and performance as it eliminates weak points and potential failure areas.

In conclusion, deep drawn metal parts produced by deep drawing stamping are unmatched in precision, strength and cost-effectiveness. Their ability to manufacture complex shapes with extreme precision has made them indispensable in various industries. So whether you need complex automotive components or complex medical device housings, deep drawing is the answer to obtaining high-quality parts that meet your specific needs.

Post time: Jul-25-2023